The system is centred on a 1U coordinator unit which provides serial control of eight VTRs or ATRs. This unit also has sixteen GPI lines which may be used to control secondary off-line recorders. Separate desktop panels are connected to the coordinator unit to control the machines connected to the system. Each desktop panel is able to control the operation of three machines simultaneously. A maximum of five desktop panels may be connected to a coordinator unit.

An alternative version for use with Digital Audio Workstations (DAW) in audio post-production studios is also available. This supports up to three control panels and two DAWs. Machines assigned to panel A can also be controlled and synchronised by DAW A. Similarly, machines assigned to panel B can also be controlled and synchronised by DAW B.

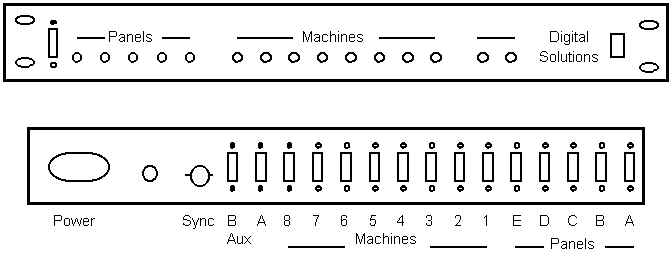

Coordinator unit

This 1U rack contains six microprocessors and fourteen RS422 9pin serial interfaces. Eight of the 9 pin ports on the rear panel are used to control the operation of machines 1-8. These ports are controlled by the central system processor via FIFO buffered UARTs. Each of the remaining rear panel 9 pin ports is directly connected to an individual sub-processor board (five in all). These sub-processors provide control and display information to the desktop control panels. The rear panel also contains connectors for the Aux A port (eight S.P.N.O. relays outputs), the Aux B port (eight logic level I/O lines), the video sync reference input, and the Mains power (100 - 240 VAC) input. The front panel of the Coordinator Rack contains fifteen tri-colour status LEDs, the fourteenth RS422 9 pin port connector, and the unit power switch.

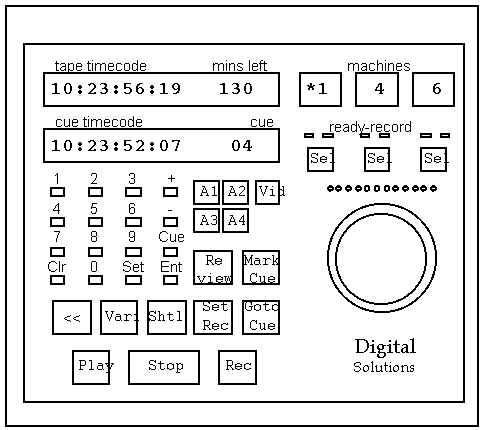

Desktop control panels

These mains powered units are each used to control up to three of the machines connected to the coordinator rack. Eighteen illuminated control keys, a sixteen key numerical keypad, and a jog / shuttle control are used to select transport modes. Cue points and other timecode functions may be modified using the keypad.

Timecode values and system status information is displayed by the three areas of dot matrix LEDs (thirty eight characters in total). The rear panel contains a RS422 connector for communication with the coordinator rack, an external command input socket, Mains input, and the power switch.

The overall size of each panel is approximately 220 mm wide,

215 mm front - rear, and 95 mm high at the rear edge sloping down

to 45 mm high at front edge.

System operation

The software developed for this system is designed to by used

by number of operators in a television production gallery, or in

multi studio post-production. Each operator has a desktop control

panel and is able to control machines for ganged record bank

program recording, isolated recording, recording review, insert

edit recording, assemble edit recording, and pre-recorded

material playback. The control of machines may be transferred

between operators as needed.

Each panel may select up to three machines to control. The

machine to be controlled is selected by holding down one of the

three SEL buttons and pressing the machine number on the keypad.

If the desired machine is already assigned to another panel a

message will inform the operator, otherwise the status of the

machine and it's current time code will be displayed. The mode of

machine operation may be select to be 'R' (recorder), 'P'

(player), or '<' (synchronised slave). Control of each machine

is enabled/disabled by pressing the appropriate SEL button. The

assignment of the machine to the panel is cleared by use of the

SEL button and the CLR key.

Various types of recording operation are supported by the system.

These include Manual Crash Record, Manual Insert Edit, Auto

Insert Edit, Auto Assemble Edit, and a special mode for studio

production recordings called 'No Over Record' which prevents the

system from erasing (recording over) any previous takes. The

operation of the system in this mode is described below.

Recording operations are enabled by selecting the machines to be

controlled, pressing the VID button to enable crash recording

mode, and then pressing the SET REC key. The system will then

perform a series of transport motion commands which ensure that

each selected machine is positioned one second beyond the last

section of program recorded on the tape. This process is designed

to ensure that it is not possible to record over any previous

program material. Whilst this process takes place the amber READY

indicator above each selected machine's SEL button will flash.

This indicator will glow steadily once the machine is correctly

positioned. When all the selected machines are correctly

positioned, the SET REC key will also become steadily lit.

Recording operation may now be initiated by pressing the PLAY and

REC keys simultaneously. A 10 second count-down is displayed to

assist the cueing of artistes. The state of each machine is

monitored throughout a recording. A red RECORD indicator above

each SEL button will glow steadily during normal recordings. This

indicator will flash if that machine reports any recording

difficulties. The timecode value of the first frame of stable

recording for each machine is stored to permit review once the

recording has been terminated by pressing the STOP key. The

record entry times for each of the last 19 recordings of each

machine are stored. The REVIEW key is used to step through this

list and locate the machine(s) to the entry point of previous

recordings.

Audio channel only INSERT recordings may also be initiated. This

is enabled by selecting the channels to be enabled for recording

by used of the A1 - A4 keys.

Machines may be controlled for playback operation. Each control

panel is able to store 99 cue points which may be used to mark or

locate sections of program by means of the MARK CUE and GO TO CUE

keys. Cue points may also be entered and revised by use of the

numeric keypad.

The VARI key enables varispeed playback. The speed of playback

may be adjusted using the jog / shuttle control whilst holding

down the VARI key. The new setting is stored for later recall.

The system provides synchronised playback or recording

facilities, and support for shared machine control with digital

audio workstations.

The control panel may also be used to set and display timecode

generator USER BITS, and to view the tape time remaining on each

machine if the controlled transport provides this information.

Special support is provided to improve the operational

performance of the controlled machines. Special functions are

provided for D-VTRs (D3, DVW), Sony BVU series, and DAT machines.

The Aux A GPI port of the coordinator unit may be used provide

howl round suppression and line-up lockout control. The system

monitors the status of machines 1-4 and uses this information

control this port.

The Aux B GPI port of the coordinator unit may be used to control

four off-line (VHS) recorders. The system monitors REC and STOP

commands as they are sent from machine ports 1-4 and uses this

information to command the off-line recorders to change mode.

The indicators on the front panel of the coordinator unit show

the communication status and machine assignments for the system.

The front panel RS422 9 pin port provides serial data display of

the timecode, transport mode, machine type, and assignment of

each machine connected to the system.

All indicators on the coordinator unit and the desktop control

panels use LEDs.

Digital Solutions (UK) Limited

109 Byewaters

Watford

WD18 8WH

Phone: (+44) (0) 1923 213233

email:

info@digitalsolutions.co.uk